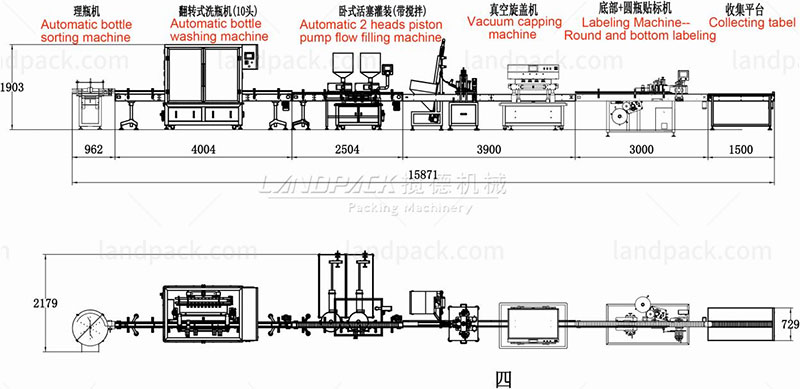

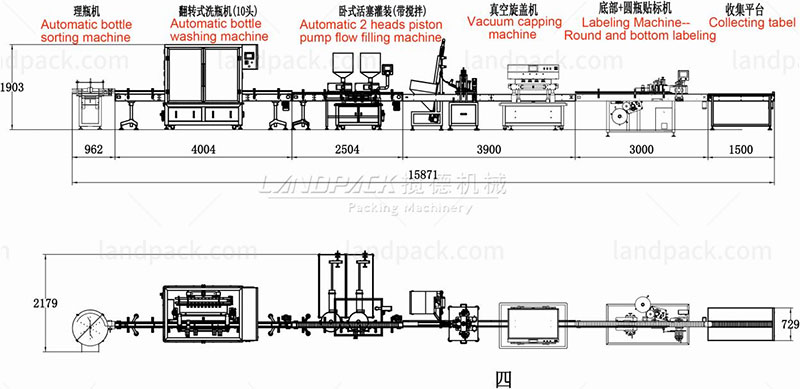

Theme: Caviar Jar Filling Capping Labeling Line

Published by: Karen-Landpack

Country: Russia

Customer: Company CA

Product: Caviar

Packing by: Jar

The Target & Challenge:

Product: Caviar

Container: Jar

Requirement:

1. Good working efficiency

2. Stable and long-time running machine

3. Good quality

4. Beautiful performance

5. 2500 jars/hour

How We Did It (Solution):

Two flow piston pump filling machine Main feature

1. The container is pushed into the bottle sorting machine, and the container can be input to the production line conveying belt one by one through the rotary table rotation, and to enter the next step.

2. The automatic 12-head bottle washing machine is mainly used to rinse glass and PET bottles before filling. It mainly consists of bottle feeding, bottle grabbing, inversion, rinsing, water control, inversion reset, bottle out, and other processes. It runs fully automatically and is stable and reliable.

3. Automatic 2 heads liquid pump filling machine widely used in drinks, wine, water, vinegar, alcohol, and other viscous liquids.

4. The fully automatic vacuum capping machine simulates manual capping action, and the capping process does not damage the bottle cap. Compatible with multiple bottle types, it can achieve a vacuum capping effect. Working process of capping machine: Covering - Spinning - Finished product output.

5. Labeling machine, using intelligent programming and touch screen control, easy to use and set up, the scope of application is wider, which can meet the single labeling of round bottles or polygonal bottles.

6. Finish product collection platform, for workers to do the next step for the finished product.

The Caviar Jar Filling Capping Labeling Line picture as below:

Feedback:

"We are very satisfied with this machine. And believe very soon our product could occupy a larger market share."