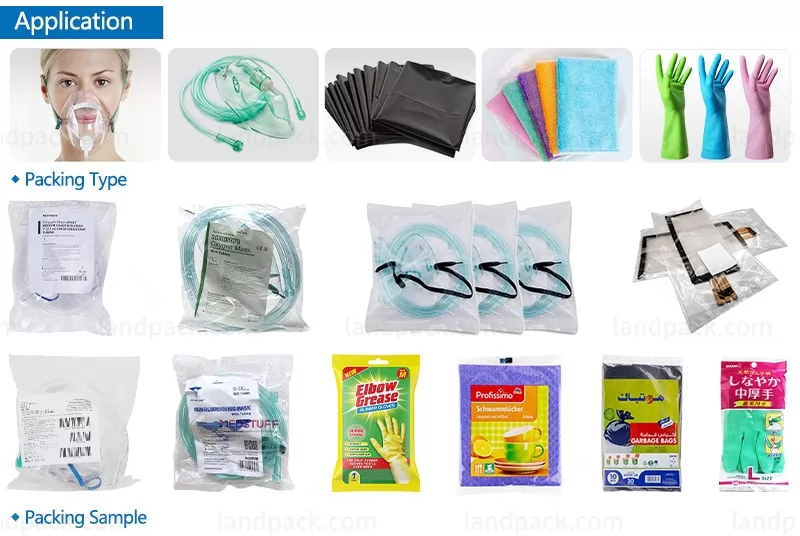

1. Suitable for Various Film Materials: Applicable to PE, PET/PE, all composite films and degradable films which remarkably reduces production cost.

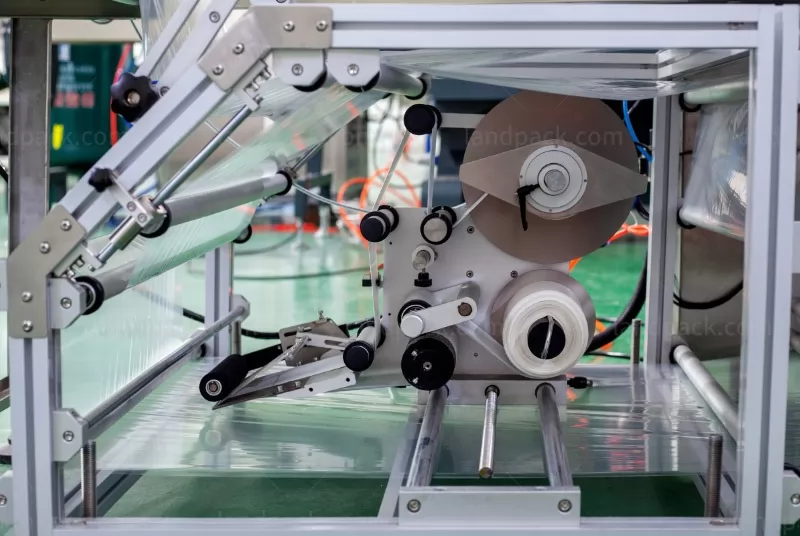

2. Integrated Punching Device: It makes ventilation holes directly on the film, enabling medical products to enter the sterilization environment and fulfill hygiene standards.

3. Smooth Labeling Integration: A labeling machine will be used to apply labels on each bag, making product identification easier for customers.

4. Flexible and Adjustable: With adjustments made possible for packaging products of various sizes, and an easy-to-operate design.

5. High Speed & Efficient Performance: Designed to give you fast production rates without compromising precision and repeatability.

6. Use of advanced PLC control system: Make sure the machine will work stably, with touch-screen operation, and intuitive, and simple parameter settings.

7. Stainless steel design: Long-lasting as well as meets hygiene factors and is resistant to rust

8. Seamless integration into production lines: Can connect upstream and downstream equipment to form a fully automated packaging solution.

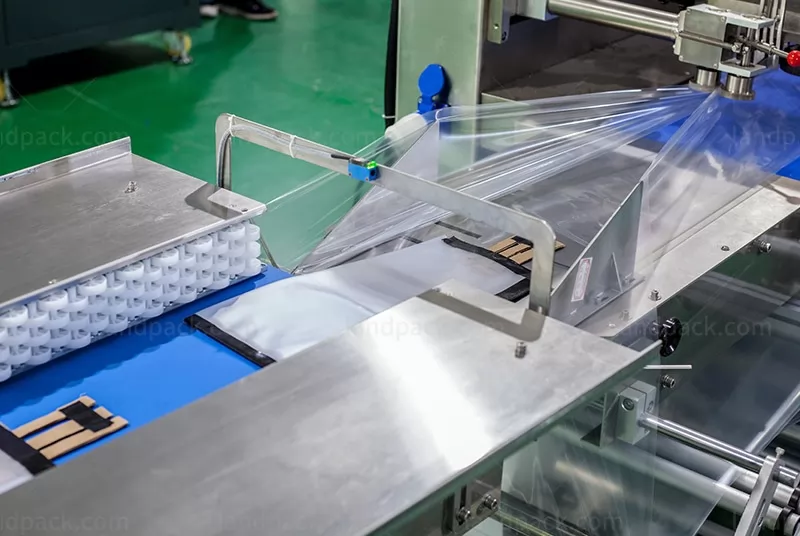

Workflow:

1. Pounch the hole on bag

2. Stick the label on bag

3. Feeding material to pack

4. Eyes sensor to identify the position

5. Sponge Exhaust Device

6. End sealing device

7. Output the finished product