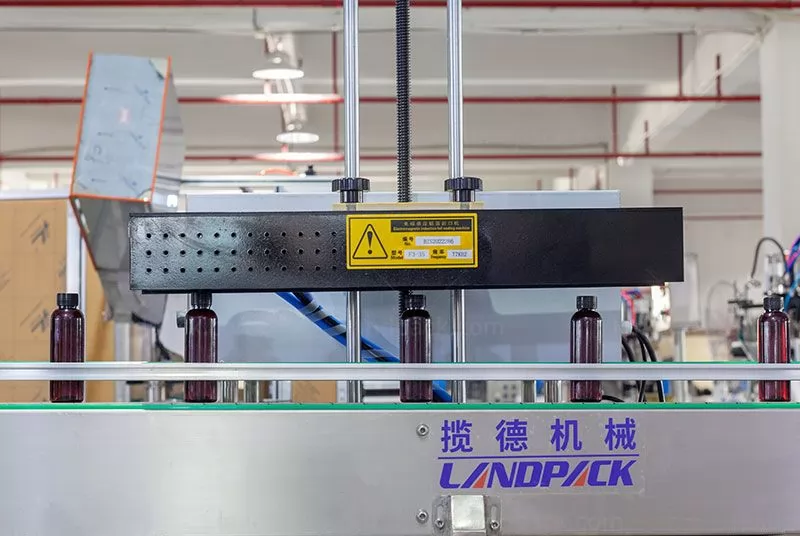

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, and pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, and good stability, and is well-received by users;

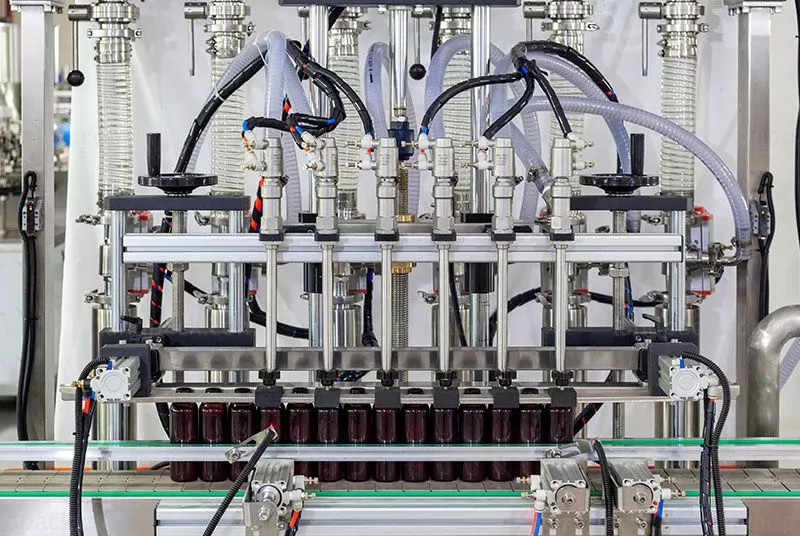

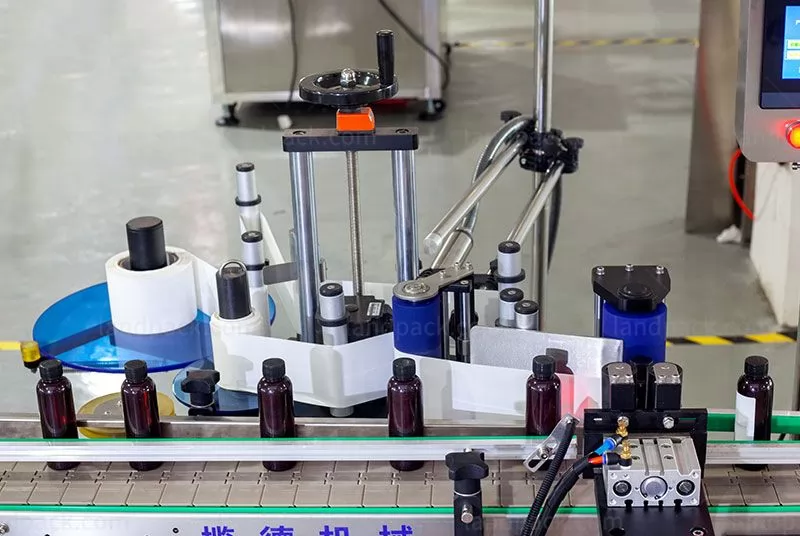

2. This line uses automatic bottle feeding, a 6-head servo piston filling machine, automatic elevator capping, servo screw cap, wafer positioning round bottle labeling machine, and bottle collection to form a fully automated production line;

3. The filling machine uses food-specific hoses and does not contain plasticizers, which is suitable for medicine, food, and other industries;

4. The piston cylinder of the filling machine adopts a grinding and wear-resistant metering cylinder, which can automatically compensate the piston seal for long life;

5. The capping machine uses a manipulator to grasp the cap, press the cap, and control the capping torque through a servo motor to achieve the capping effect;

Complete set, the whole line is fully automatic, saving labor;

6. This type of capping machine has uniform force for capping, easy to adjust the force, and it is not easy to wear the cap;

7. The production line has stable operation, low noise, convenient maintenance, fully meets GMP certification requirements, and is widely used in medicine, food, cosmetics, and other industries;

8. The whole machine is made of corrosion-resistant stainless steel, which is easy to clean and disinfect, and meets the national regulations and requirements on food machinery and food hygiene;

9. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

10. This kind of production line is relatively advanced, can be improved according to the different requirements of customers, and can be made into equipment that fully meets customers' needs. The plexiglass cover of the whole machine is designed to prevent impurities from entering the filling material, which is safe and hygienic;

11. Customize the size of the whole line according to the plant space;

12. Can switch different capacity bottle filling, simple operation, strong flexibility;

13. Automatic filling, capping, labeling, screen memory parameters, change the bottle type, change the parameters can be.