In an era of increasing consumer demand for convenience and efficiency, sachet and stick pack packaging machines have become indispensable tools across industries. Whether for food, pharmaceuticals, cosmetics, or chemicals, these machines provide a versatile solution for packaging powders, liquids, and granules. Compact, cost-effective, and eco-friendly, sachets and stick packs offer the perfect solution for modern packaging needs. This article dives deep into the different types of sachet and stick pack packaging machines, their advantages, and real-world applications. We will also explore how these machines contribute to increased productivity and sustainability.

Importance of Sachet and Stick Pack Packaging

Sachets and stick packs are lightweight, portable, and designed for single-use servings, making them highly popular in today's fast-paced, on-the-go world. This packaging format offers both consumers and manufacturers substantial advantages, including cost reduction and product longevity. A 2022 report by Market Research Future projects that the sachet packaging market will grow at a CAGR of 6.5% through 2030.

1. Consumer Convenience: Sachets and stick packs provide easy-to-use, single-serving options, making them perfect for individual consumption.

2. Cost-Effective: These compact packages reduce material usage and shipping costs, making them a budget-friendly solution for many businesses.

3. Long Shelf Life: High-quality sealing technologies ensure that products stay fresh longer, even when exposed to environmental factors.

4. Sustainability: By using minimal material compared to traditional packaging, sachets and stick packs support sustainability efforts and reduce plastic waste.

Types of Sachet and Stick Pack Packaging Machines

Both sachet and stick pack packaging machines are highly customizable, depending on the material, package size, and production requirements. Below is an in-depth exploration of the different types of machines:

Sachet Packaging Machines

1. Horizontal Sachet Packaging Machine

- Applications: Ideal for packaging masks, cards, wet wipes, plaster paste, analgesic paste, foot patches, eye patches, warm patches, fast heat patches, etc.

- Working Principle: This machine works by pulling a roll of film through a series of forming stations. The film is shaped into a sachet, filled with the product, and sealed. The horizontal orientation allows for fast packaging of products in larger volumes.

- Advantages:

* High-Speed Production: Capable of high throughput, making it suitable for large-scale operations.

* Customizable Sachet Sizes: Accommodates various sachet sizes and shapes, offering flexibility for different products.

* Efficient Packing Systems: Provides precise packing, ensuring minimal waste.

2. Vertical Sachet Packaging Machine

- Applications: Best for packaging powders (detergents, coffee powder, etc), fine granules, and viscous liquids (honey, oils, etc).

- Working Principle: The vertical form-fill-seal machine uses a continuous roll of film, which is formed into a tube, filled with the material, and sealed vertically. It offers a compact design that requires minimal floor space.

- Advantages:

* Space-Efficient: Ideal for factories with limited space, as it has a smaller footprint.

* Cost-Effective: Lower operational costs compared to other machines, especially for small to medium production runs.

* Versatility: Can handle various product types, from powdered to liquid-based products.

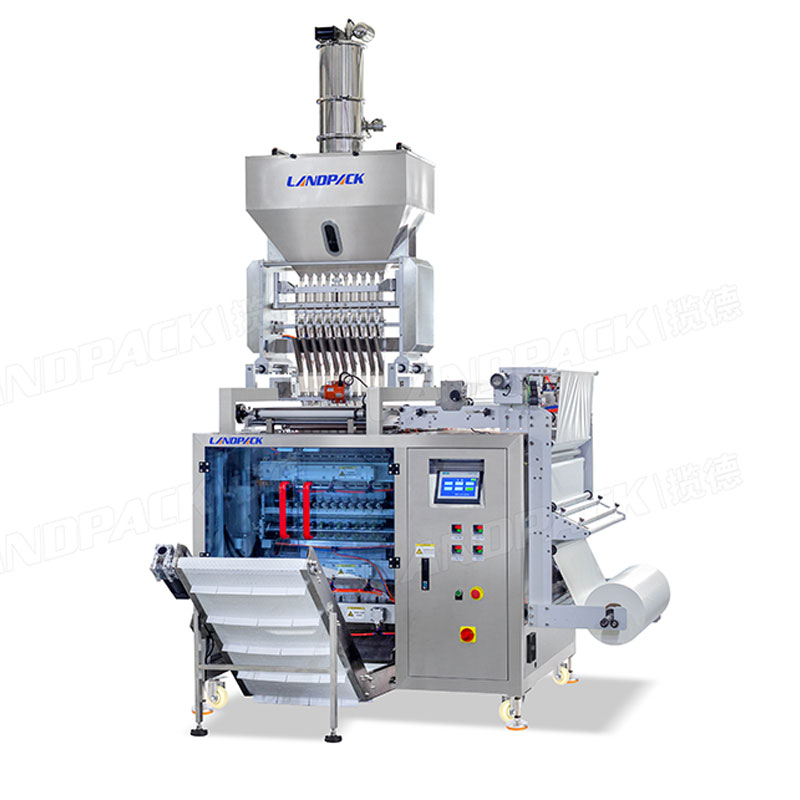

3. Multi-Lane Sachet Packaging Machine

- Applications: Ideal for high-volume packaging of powders (e.g., instant coffee, protein powders), granules (e.g., sugar, salt), and liquids (e.g., ketchup, shampoo) into compact sachets. These machines are widely used in industries such as food, beverages, cosmetics, and pharmaceuticals.

- Working Principle: The sachet multi-lane packaging machine operates by forming sachets from a continuous roll of film across multiple lanes simultaneously. Each lane fills the sachet with the designated product, seals it, and cuts it into individual packets. The multi-lane design drastically enhances production speed while maintaining precision and consistency.

- Advantages:

* 1. High Efficiency: Capable of producing multiple sachets simultaneously, significantly increasing production output. Perfect for businesses with large-scale demands.

* 2. Customizable Lane Options: Available with various lane configurations (e.g., 4, 6, 8, or more) to accommodate different production requirements and sachet sizes.

* 3. Precise Filling: Equipped with advanced dosing systems, ensuring accurate portioning of powders, granules, and liquids, minimizing product waste.

* 4. Flexible Sachet Formats: Supports a wide range of sachet shapes and designs, including rectangular, square, and tear-notch sachets, catering to diverse market needs.

* 5. Space Optimization: Despite its high-capacity output, the multi-lane design maximizes vertical use of space, making it ideal for factories with limited floor area.

Stick Pack Packaging Machines

1. Single-Lane Stick Pack Machine

- Applications: Perfect for small-scale production of powders (protein powders), liquids (energy gels), and granules.

- Working Principle: The single-lane machine feeds the packaging material through a vertical forming station. It then fills each tube with product before sealing it into a stick pack. The simplicity of the design makes it easy to operate and maintain.

- Advantages:

* Cost-Effective for Small Batches: This machine is affordable for startups and small businesses.

* Simple Operation: The user-friendly interface makes it easy for operators to learn and maintain the machine.

* Compact Design: Ideal for businesses with limited production space.

2. Multi-Lane Stick Pack Machine

- Applications: Suited for high-volume production in industries such as food, beverages, and pharmaceuticals.

- Working Principle: The multi-lane machine operates several lanes simultaneously, increasing throughput. It forms, fills, and seals multiple stick packs in parallel, making it perfect for mass production.

- Advantages:

* Increased Production Capacity: Capable of handling high-speed operations with multiple lanes, reducing overall production time.

* Reduced Downtime: Automation minimizes downtime, ensuring continuous operation.

* Precision and Minimal Waste: Multi-lane machines ensure precise filling with minimal material wastage.

Sachet and Stick Pack Cartoning Machines

Sachet/stick cartoning machines are designed to efficiently pack multiple sachets/sticks into cartons, ensuring they are securely arranged and ready for retail or distribution. These machines can handle a wide range of carton sizes, offering flexibility for various product lines.

- Working Principle

* Carton Forming: The machine automatically forms flat carton blanks into open cartons.

* Product Loading: Pre-packaged sachets/sticks are automatically grouped and loaded into the cartons using precision systems.

* Carton Sealing: After the sachets/sticks are inserted, the cartons are sealed using glue or tuck-in flaps, depending on the packaging design.

- Key Features and Benefits

* Automated Grouping: Ensures sachets/sticks are neatly organized for efficient loading.

* Flexible Carton Sizes: Accommodates various carton dimensions to match branding and retail requirements.

* High Speed: Handles high-volume production lines, increasing efficiency.

* Enhanced Branding: Cartons provide additional space for product information, branding, and marketing designs.

- Applications

* Food Industry: Packets of sugar, coffee, or spices grouped into cartons for retail.

* Pharmaceuticals: Medicine sachets/sticks bundled for easy dispensing in pharmacies.

* Cosmetics: Single-use lotion sachets/sticks arranged in branded cartons.

Advantages of Sachet and Stick Pack Machines

1. Versatility Across Different Materials:

- Powders: Coffee, tea, protein powders, and spices.

- Granules: Sugar, salt, and dietary supplements.

- Liquids: Sauces, oils, syrups, pharmaceutical solutions, and cosmetics.

2. Industry Applications:

- Food and Beverages: Sachets for condiments (salt, sugar) and stick packs for energy drinks or protein shakes.

- Pharmaceuticals: Precise dosing of medication, powders, or liquids in easy-to-carry packs.

- Cosmetics: Single-use sachets for samples of creams, lotions, and shampoos.

- Chemicals: Packaging for industrial liquids or adhesives in controlled doses.

3. Enhanced Branding and Market Differentiation:

- Custom printing options allow for vibrant designs, which can help your product stand out on shelves.

4. Efficiency in Operation:

- The high-speed automation of these machines reduces labor costs and increases overall productivity, while advanced sealing techniques minimize product waste.

Why Choose Landpack for Sachet and Stick Pack Machines?

Landpack is recognized as a leading manufacturer in the sachet and stick pack packaging machines market. With years of expertise, a commitment to quality, and cutting-edge technology, Landpack offers tailored solutions for various industries. Here's why Landpack is a preferred choice:

1. Customized Solutions: Landpack offers machines that cater to a wide range of materials (powders, liquids, granules) and production requirements.

2. Innovative Technology: With automation and precision sealing technologies, Landpack ensures high efficiency and low waste, helping businesses reduce operating costs.

3. Global Trust: Landpack's machines are trusted by businesses worldwide for their reliability and superior performance.

4. Comprehensive Support: From initial consultation to after-sales service, Landpack provides exceptional customer service to ensure smooth operations and high satisfaction.

Industry Trends and Future of Sachet and Stick Pack Packaging

The sachet and stick pack packaging market is seeing a shift towards greater customization, with more demand for eco-friendly packaging options. Brands are increasingly adopting recyclable and biodegradable materials to appeal to environmentally conscious consumers. Automation is also playing a larger role, with machines becoming more intelligent and capable of handling a wider range of products.

Additionally, advancements in digital printing allow for better branding opportunities, enabling brands to create personalized packaging that resonates with their target audience. Industry experts predict that the demand for sachet and stick pack machines will continue to grow as consumer preference for convenient, on-the-go products rises.

Conclusion

Sachet and stick pack packaging machines are revolutionizing the packaging industry by offering convenience, versatility, and cost-effectiveness. These machines meet the evolving demands of various industries, including food and beverages, pharmaceuticals, cosmetics, and chemicals. By investing in high-quality packaging machines like those from Landpack, businesses can streamline operations, reduce costs, and stay ahead of the competition.

Whether you're looking to package powders, liquids, or granules, Landpack provides the ideal solutions for your business. With cutting-edge technology and comprehensive support, Landpack ensures that your packaging needs are met with efficiency, precision, and sustainability.