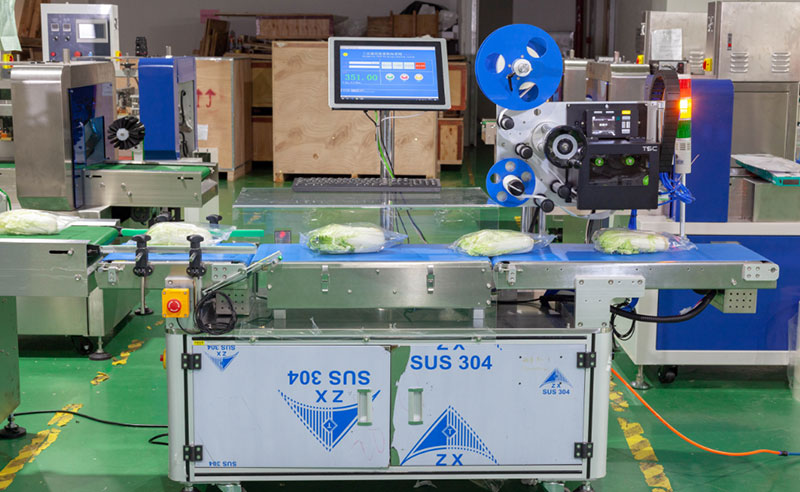

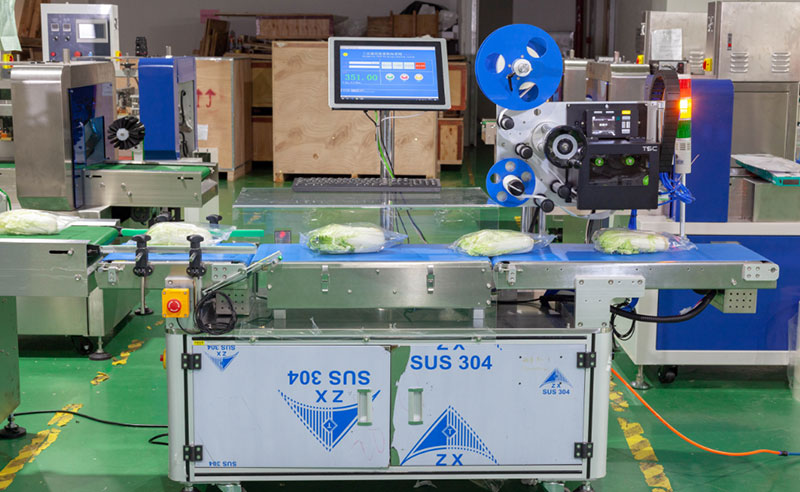

The daily maintenance of vegetable packaging machine equipment is very important. Good mechanical maintenance can not only enable mechanical equipment to be used for a long time, but also reduce the frequency and cost of equipment maintenance, and further improve production capacity and efficiency.

Mechanical equipment includes the following important steps. Cleaning, tightening, adjusting, lubricating, and anti-corrosion work. If you do the following points, you can ensure that the life of the packaging machine equipment can be extended. Mechanical maintenance personnel should pay attention to the maintenance manual and maintenance procedures of the machine packaging equipment, and carry out daily maintenance of the equipment according to the instructions. Strictly carry out maintenance work, reduce the wear rate of parts, eliminate hidden dangers, and prolong the service life of the machine. The maintenance work of packaging machinery and equipment includes daily maintenance, regular maintenance, and special maintenance. Regular maintenance can be divided into primary maintenance, secondary maintenance, and tertiary maintenance. Special maintenance can be divided into seasonal maintenance and seasonal maintenance.

Daily maintenance:

Maintenance focuses on cleaning, lubricating, inspection, and tightening, with routine maintenance as required during and after machine operation.

Regular maintenance:

The main maintenance work is carried out on the basis of daily maintenance, and the key work content is the lubrication, tightening, and inspection of related parts and their cleaning.

The focus of secondary maintenance work is inspection and adjustment. Specific inspection of engine, clutch, transmission, transmission, steering, and brake components.

Level 3 maintenance focuses on detecting, adjusting, troubleshooting, and balancing the wear levels of the various components. Perform diagnostic tests and status checks on components that affect equipment performance and symptoms of failure, and then complete necessary replacement, adjustment, and troubleshooting.

Seasonal Maintenance:

Due to the changing seasons, the use of the device can be affected by warm and cold weather. Such as mechanical looseness, rust, etc. Attention should be paid to the power system (engine), conveying system (screw shaft and belt conveyor), air pressure system (checking the lubrication and sealing of the air compressor), control system (maintenance of the Youte mechanical and electrical control cabinet, this part needs to be in Ute Completed under the guidance of after-sales engineers) and other parts inspection and maintenance.

Suspending the use of the machine or replacing it with the same package allows the machine to be better maintained, because the machine, like a human, needs rest and sleep.

Welcome to contact us for the details to provide you with the most suitable packing solution.

LANDPACK always be your best partner!