The sauce filling machine is a device used for automatically filling sauces, which can help companies improve production efficiency and ensure product quality. The following will introduce how to improve the production efficiency and product quality of the sauce filling machine from many aspects.

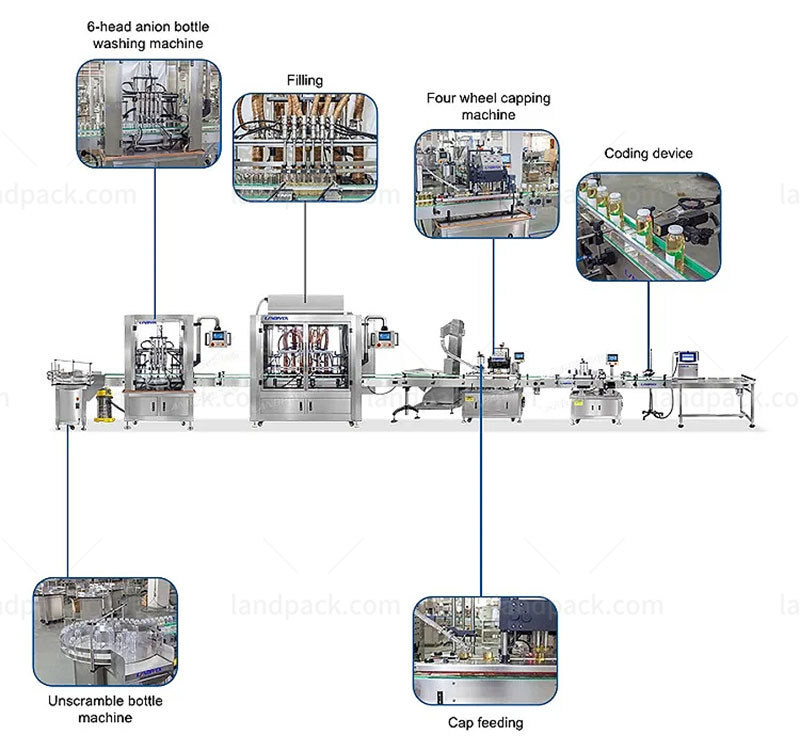

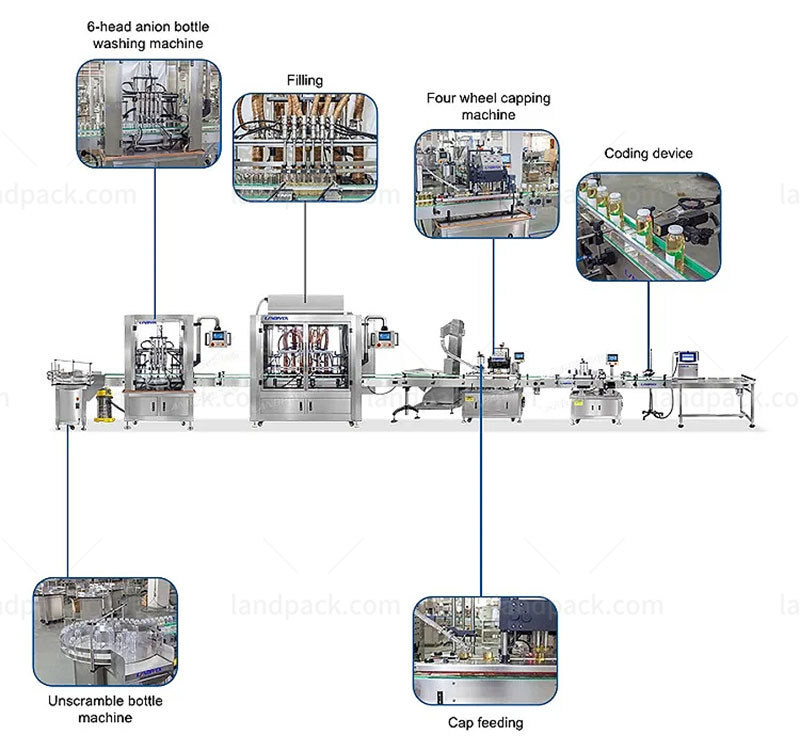

First of all, to improve the production efficiency of the sauce filling machine, the key is to improve the automation level and filling speed of the equipment. Using advanced automation control technology, the automatic operation of equipment can be realized, including automatic feeding, automatic filling, automatic sealing, etc. This can reduce manual operation time and errors and improve production efficiency. In addition, choosing a sauce filling machine with higher filling speed can further improve production efficiency.

Secondly, to ensure the product quality of the sauce filling machine, you need to pay attention to the following points. First of all, for liquid sauces, it is necessary to ensure that the temperature and viscosity of the sauce are stable so that it can flow and fill well. This can be achieved by setting up temperature control and viscosity control systems in the filling machine. Secondly, choose a filling machine model that suits the characteristics of the sauce. Different sauces may have different characteristics, such as larger or smaller particles, higher or lower viscosity, etc. It is necessary to choose a suitable filling machine to ensure product quality. Thirdly, the sauce filling machine should be maintained and maintained regularly to keep it running normally. Regularly clean and disinfect the filling machine to ensure equipment hygiene and avoid contamination of the sauce. It is necessary to carry out quality inspections during the filling process and conduct random inspections on the filled products to ensure that the product quality meets the requirements.

In addition, some other measures can further improve the production efficiency and product quality of the sauce filling machine. The first is to strengthen personnel training and improve the technical level and work efficiency of operators. Only by mastering the operating skills and precautions of the sauce filling machine can the performance of the equipment be better utilized. The second is to optimize the production process, reasonably arrange production tasks and filling sequence, and avoid wasting time idling and waiting for the filling machine. The third is to establish a complete quality management system, including full traceability and quality records from raw material procurement to finished product filling, to promptly discover and solve quality problems.

In short, to improve the production efficiency and product quality of the sauce filling machine, it is necessary to do a good job in equipment selection, automation control, product quality control, and personnel management. By continuously optimizing production processes and management, companies can achieve dual improvements in production efficiency and product quality.

Thank you for reading, please get in touch with us if you have any inquiries.

LANDPACK would be your reliable supplier of packing machines.

If you have any questions about the machine, feel free to contact us or leave your machine inquiry on our website, our sales managers and engineers will be here to support you and provide you with a suitable packing solution.

You could contact us by our website address or phone number, our sales managers will contact you in time and give you professional suggestions. And our engineers are willing to help you to solve the machine problem and teach you one step by step on video calling.