Laundry liquid detergent filling machines are essential equipment in the packaging industry, designed to streamline the process of filling liquid detergents into various containers. These machines are highly efficient, ensuring accuracy and consistency in filling. In this article, we will delve into the workings of liquid detergent filling machines, exploring their components, operational processes, and the benefits they bring to the manufacturing industry.

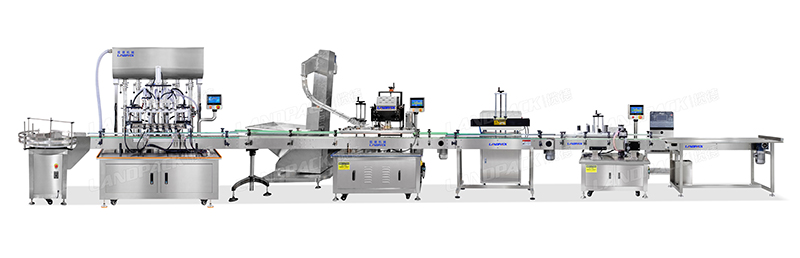

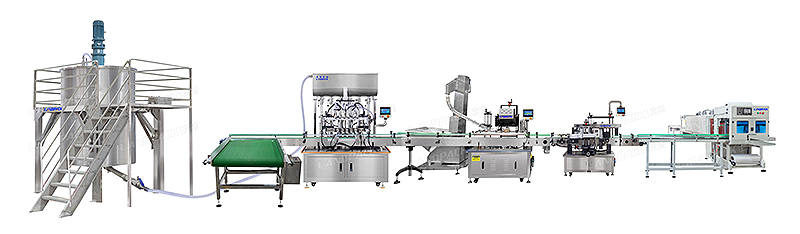

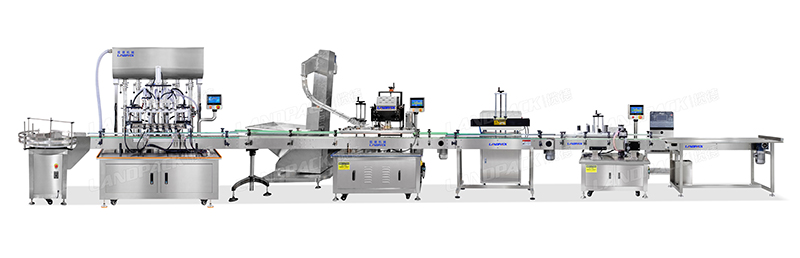

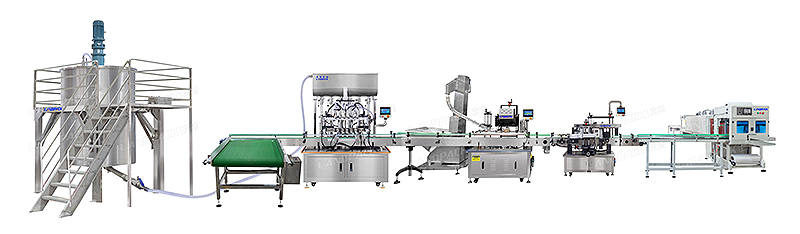

Components of Liquid Detergent Filling Machines

Understanding the various components of a liquid detergent filling machine is crucial to comprehending how these machines operate. Here are the primary components:

1. Filling Heads: These are the nozzles that dispense the liquid detergent into containers. The number of filling heads can vary depending on the machine's capacity and the production needs.

2. Conveyor System: This system transports containers to the filling station and subsequently to the capping or sealing station. It ensures a continuous flow of containers through the production line.

3. Pump System: The pump is responsible for drawing the liquid detergent from the storage tank and delivering it to the filling heads. Different types of pumps, such as piston pumps, peristaltic pumps, or gear pumps, can be used depending on the viscosity of the detergent.

4. Control System: Modern filling machines are equipped with advanced control systems, often featuring programmable logic controllers (PLCs) and touch screens. These systems allow operators to set parameters such as fill volume, speed, and other operational settings.

5. Sensors and Actuators: Sensors detect the presence of containers and ensure they are correctly positioned for filling. Actuators control the opening and closing of filling valves and other mechanical movements.

Operational Process of Liquid Detergent Filling Machines

The operation of a liquid detergent filling machine involves several stages, each meticulously coordinated to ensure precise filling. Here's a step-by-step overview:

1. Container Feeding: Empty containers are fed onto the conveyor system either manually or through an automated feeder. The containers are spaced evenly as they move towards the filling station.

2. Positioning and Detection: Sensors detect the arrival of containers and ensure they are properly positioned under the filling heads. The machine pauses briefly to ensure accurate placement.

3. Filling: The pump system draws the liquid detergent from the storage tank and dispenses it into the containers through the filling heads. The fill volume and speed are controlled by the machine's control system, ensuring consistency and minimizing spillage.

4. Capping or Sealing: Once the containers are filled, they move to the capping or sealing station. Here, caps or seals are applied to the containers to prevent leakage and maintain product integrity.

5. Quality Control: Some machines are equipped with quality control features such as weight checkers or vision systems. These features ensure that each container is filled to the correct level and that the packaging has no defects.

6. Output: The filled and sealed containers are then conveyed to the output area, where they are either packed for distribution or moved to the next stage of the production line.

Types of Liquid Detergent Filling Machines

There are various types of liquid detergent filling machines, each designed to meet specific production needs. Some of the common types include:

1. Piston Filling Machines: These machines are suitable for high-viscosity liquids and can handle thicker detergents. They operate by using a piston to draw and dispense the liquid, ensuring precise fill volumes.

2. Gear Pump Filling Machine: These machines are usually high-precision filling applications, using gear pumps to transfer liquid detergents to ensure accurate filling amounts.

3. Gravity Filling Machines: Suitable for low-viscosity liquids, these machines rely on gravity to fill the containers. They are simple to operate and maintain, making them a cost-effective option for many manufacturers.

Benefits of Using Liquid Detergent Filling Machines

Implementing liquid detergent filling machine in a production line offers numerous advantages:

1. Increased Efficiency: These machines significantly speed up the filling process, allowing manufacturers to produce large quantities of filled containers in a shorter time.

2. Consistency and Accuracy: Automated filling ensures that each container receives the same amount of detergent, reducing variations and maintaining product quality.

3. Reduced Waste: Precise filling reduces spillage and overfilling, minimizing waste and optimizing the use of raw materials.

4. Cost Savings: By improving efficiency and reducing waste, filling machines contribute to lower production costs and increased profitability.

5. Flexibility: Modern filling machines can handle a variety of container sizes and shapes, making them adaptable to different packaging requirements.

6. Improved Hygiene: Automated filling reduces the need for manual handling, minimizing the risk of contamination and ensuring that the product remains hygienic.

Conclusion

Laundry liquid detergent filling machines are integral to the efficient and precise packaging of liquid detergents. By understanding their components, operational processes, and the benefits they offer, manufacturers can make informed decisions about incorporating these machines into their production lines. With technological advancements, these machines continue to evolve, offering even greater efficiency, accuracy, and versatility in the packaging industry. Whether you are a small-scale producer or a large manufacturing enterprise, investing in a high-quality liquid detergent filling machine can significantly enhance your production capabilities and product quality.