Multiple columns of four-sided sealing pocket packaging machines are widely suitable for loose, non-viscosity in pharmaceuticals, food, daily chemicals, and other industries, and have a certain liquid particle-shaped material, powder, powder state, and granular strip shape packaging. Such as small pills, monosodium glutamate, sugar, soup, oatmeal, seeds, coffee, cold granules, capsules, tablets, etc.

What are the advantages of multi-column four-sided granular bag-type packaging machines?

1. Advanced performance, high strength, low noise, compact structure, stable operation, convenient maintenance, and long service life.

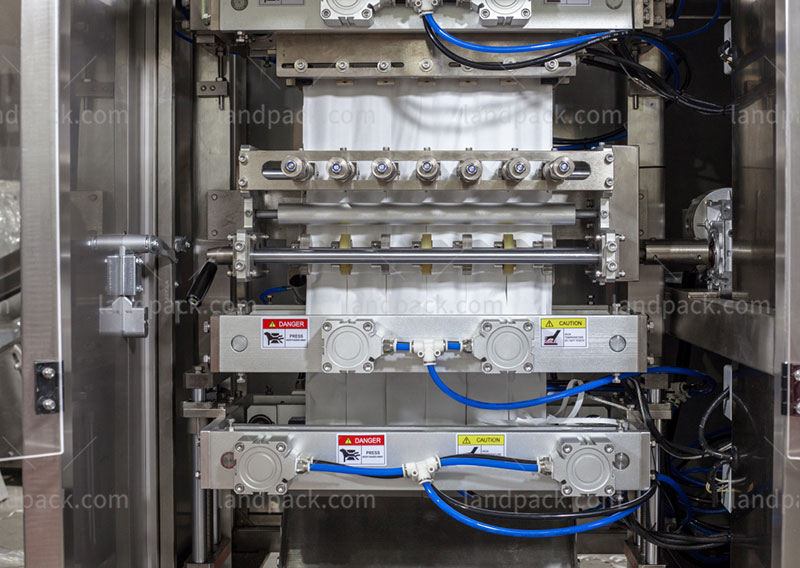

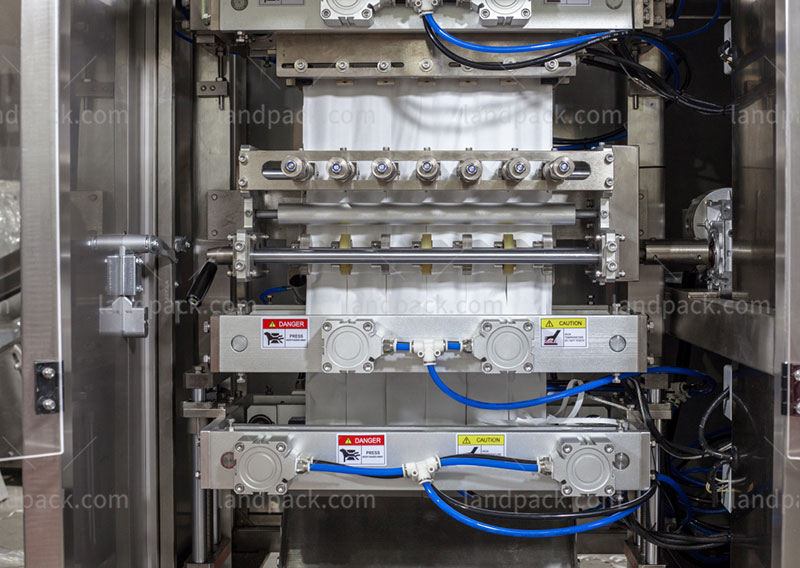

2. The degree of automation is high. This machine is completed from longitudinal sealing, longitudinal cutting, cross-sealing, filling the feed, batch number, cutting easily, cutting cracks, cross-cutting, and until the output of the finished product, and the bag can be completed at one time.

3. The drums are sealed, with four-sided sealing/four-sided sealing, multiple bag packaging at high speed, and the bag type is flat, exquisite, and the packaging efficiency is high.

4. Adjustment and convenience can be adjusted without changing the mold, and the executive agencies such as vertical sealing, horizontal seals, filling, batch numbers, cuts, and horizontal cutting can be adjusted through the human-machine interface.

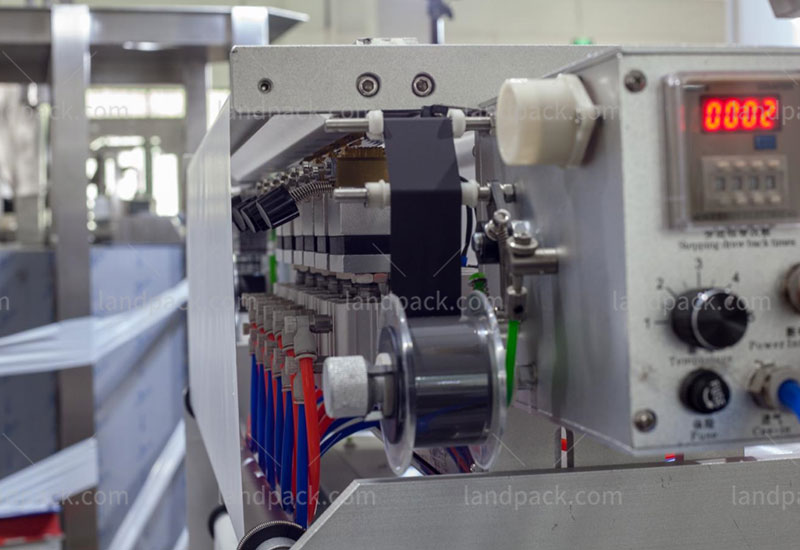

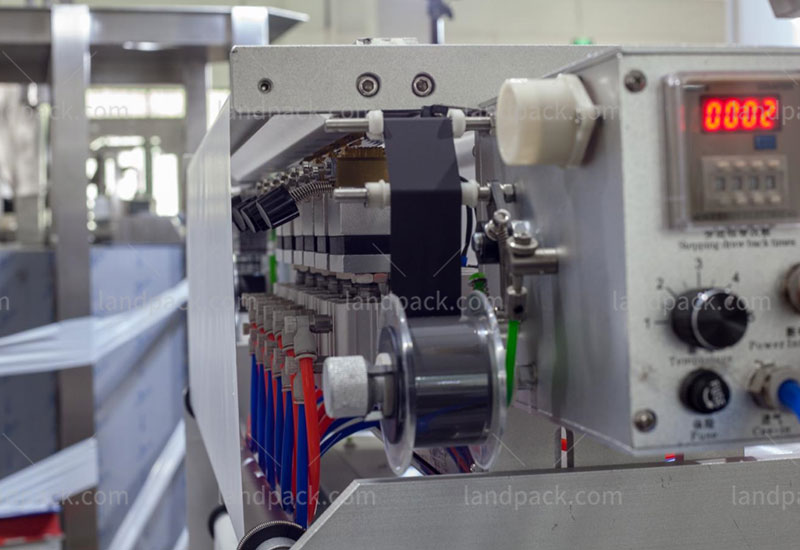

5. The filling measurement is accurate. The swing-type feeding tube is equipped with a triangular adjustable cup and the feed mechanism so that each column can be adjusted independently. At the same time, the material with poor liquidity can be configured with a lift-down vibration feeding device.

6. The whole machine is automatically controlled by PLC, and the variable frequency-free speed adjustment is used. All executive agencies are driven by servo motors. It runs smoothly and the synchronization positioning is very accurate.

7. The optoelectronic tracking system is used to ensure the automatic version of the double-sided pattern of the packaging bag and has an automatic counting function.

8. Strong adaptability to the packaging material. The hot-seal roller has a high-precision automatic temperature control function, which can adapt to a variety of packaging documents produced at home and abroad, such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE, etc.

9. Strong applicability. The cutting method can be selected at the same time, and it can be selected with a flat-cut and continuous bag. The ink wheel printer and various automatic alarm stops can be selected.

10. Multi-row packaging machines generally have a large output when the amount is small. The speed is relatively fast for pharmaceutical industries with an annual output of 30 million bags of particles.

Technical parameters of multiple columns of four-sided sealing particle bag type packaging machine:

Model: LD-480G

Packing Speed: Max.40 cycles/min

Max. Film Width: 960mm

Bag Form: Four-side sealing

Power: 220V, singple Phase, 0.8 MPA, 2.8kw

Main motor power: 1.81kw

Noise: ≤75db

Net Weight: 800kg

Machine size: 9850*1470*1750mm

Welcome to contact us for the details to provide you with the most suitable packing solution.

LANDPACK always be your best partner!