Sauce Sachet Filling Machine Description:

Sauce filling machine can be workable for for filling hot sauce, tomato paste,soybean sauce and etc.One machine can adjust and meet different sachet size.

Even for same types of liquid sauce, you could face lots of different choice. You’ll have to consider you sachet style, daily production need, sauce feature etc.

Let us take hot sauce business as an example to explain more details to help you find a perfect solution at different business stage.

Below are the top 2 of the most popular sauce filling machine in sauce market:

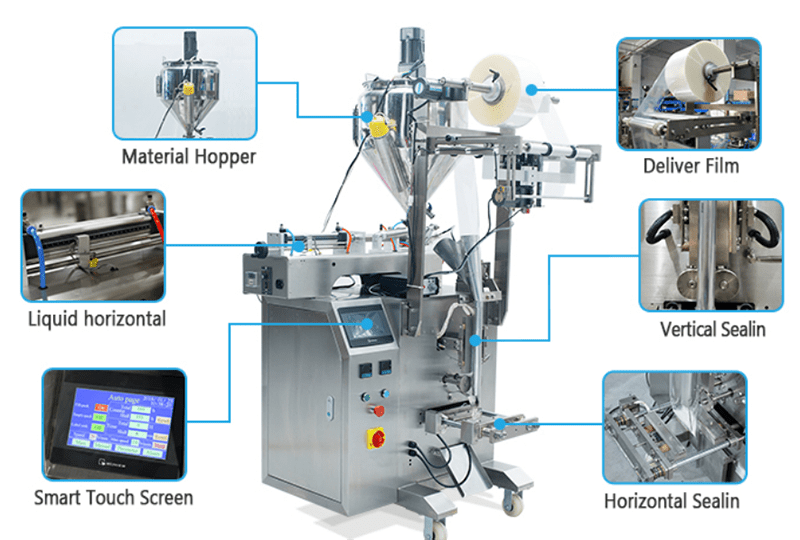

Single-Lane Hot Sauce Sachet Filling Machine Features:

1.30L standard hopper suitable for small scale business.

Stirring device and thermal device workable for option when packing some thick liquid like honey, chocolate jam, etc

2.Piston Liquid pump is flexible to change the measuring range and to pack different bag size

3.Small Space Occupied Main Packer include date printer and simple operation panel

4.This machine is one of the most popular option for start up business, because of small space occupied, and very cost effective. A great option to save lots of labor cost in long-run. Specially perfect for you while you are running a small start up business or big business of packing small liquid sachets, it can be one of your great option.

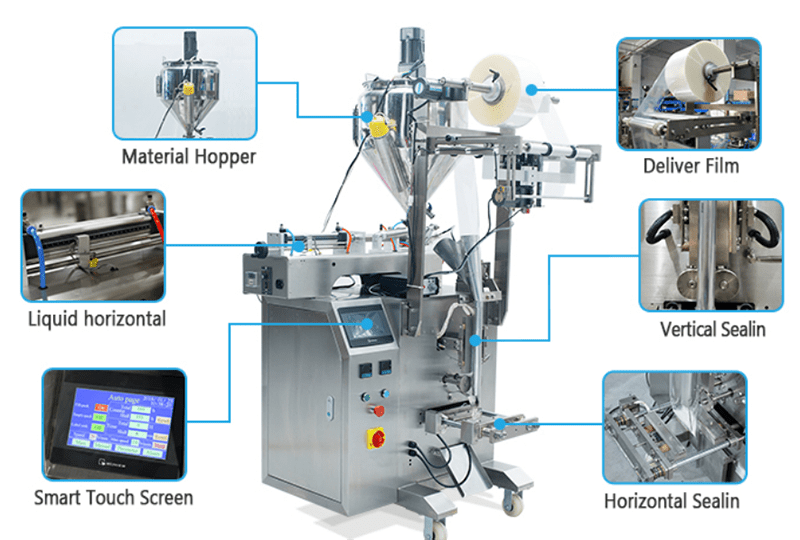

Multi-Lane Hot Sauce Sachet Filling Machine Features:

1. High production capacity: 4 lane, 6lane, 8lane, 10 lane can be selected according to the capacity requirements, so one machine production capacity equals to multiple small machines running at the same time.

2. Perfect packaging effect: Compared with single lane small machine, multi-lane packing machine is servo motor control, much smart and stable, and the material with higher precision, so finished sachets are more accurate and tight-seal;

3. Double-layer stainless steel hopper design, accompanied with thermal and mixing functions, especially suitable for viscous materials, which can fully stir the liquids and filling evenly, keep the original taste of the product.

4. UV disinfection is adopted before packaging film roll turning into bags. It's consistent with food hygiene and safety;

5. Simple to Operate, special machine for special use, no need frequent debugging to switch different modes, all parameters are pre-set in factory, only simple parameter settings on the screen, then can be used;

6. Save your space, replace multiple small machines, one multi-lane machine can achieve same goals, that can greatly save floor space and power consumption, thereby saving factory operating costs.

7. Convenient cleaning and simple after-sales maintenance: can reduce downtime and ensure good production efficiency

Summary

If you never in sauce business before and now planning a new one to test the market, apparently, the single lane filling machine will be your first choice.

If you already has sauce product selling at the market and you forecast it’ll have great chance in following 3~5years, and you prefer to expand your market share, you could consider to try one or several of multi-lane sachet filling machine to increase current production capacity, 4-lane to 10lanes are flexible to choose base on your business plan.