In today's competitive market, the protein powder packing machine is not only a vital component in the manufacturing process but also a key factor in ensuring product quality and consumer safety. Whether you are in the business of producing chia protein powder or other high-demand supplements, investing in advanced packing technology can significantly boost your production efficiency. In this comprehensive guide, we will explore every aspect of protein powder packaging—from the science behind protein powders to the advanced machinery used for packaging, including solutions from industry leader Landpack Packaging Machinery Co., Ltd. Let's dive in!

Protein Powder – What Is It and Why Is It Taking the Fitness World by Storm?

Protein powder has experienced explosive growth over the past decade. As consumers become more health-conscious, the demand for convenient nutritional supplements has skyrocketed. Protein powders, whether derived from whey, soy, pea, or chia seeds, offer a quick and easy way to boost daily protein intake, support muscle growth, and maintain overall health.

Today, the protein supplement market is thriving due to several factors:

- Fitness and Wellness Trends: The rising popularity of gym culture and healthy lifestyles has driven the demand for protein-rich products.

- Convenience: Protein powders provide an effortless solution for people with busy schedules who want to maintain a balanced diet.

- Innovation in Flavors and Formulations: Manufacturers continuously experiment with new flavors and ingredients to cater to diverse consumer tastes.

As the popularity of protein powders continues to grow, so does the need for state-of-the-art protein powder packing machine technology. Modern packaging machines not only ensure the accurate dosing of protein powders into containers but also protect the product from contamination and extend its shelf life.

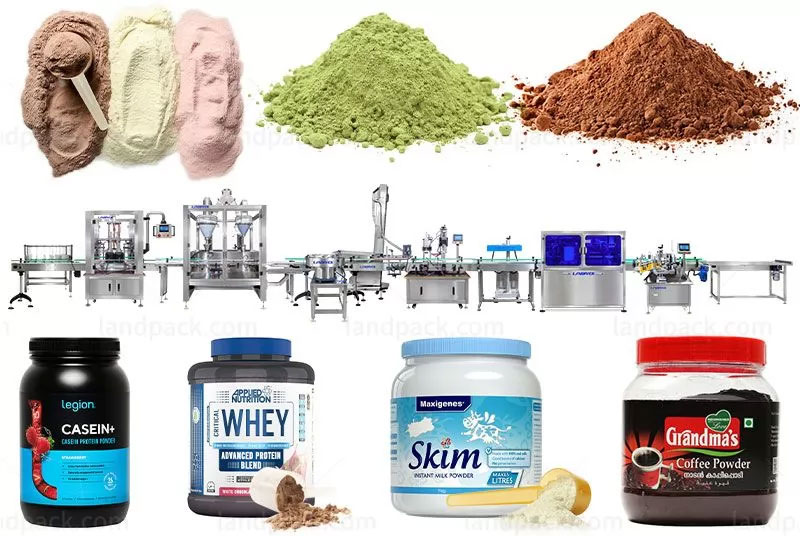

Different Types and Uses of Protein Powders

Protein powders are available in various formulations, each designed to meet different nutritional needs. Below is an overview of the most common types:

1. Whey Protein Powder

Whey protein is the most popular type, favored by athletes and fitness enthusiasts. It is known for its quick absorption rate, making it ideal for post-workout recovery. Manufacturers use protein powder packing machine technology to precisely package whey protein into containers that preserve its quality and nutritional benefits.

2. Casein Protein Powder

Casein protein, unlike whey, is absorbed more slowly, providing a sustained release of amino acids. This makes it perfect for consumption before bedtime to support muscle repair overnight.

3. Plant-Based Protein Powders

Plant-based options, such as soy, pea, and rice protein, have become popular among vegetarians and vegans. Among these, chia protein powder packing machine systems are tailored for specialized ingredients like chia, ensuring that the delicate protein content is preserved during packaging.

4. Mixed Protein Powders

Some products combine different protein sources to provide a balanced profile of amino acids. Multi-ingredient formulas require sophisticated packing lines that can handle varying densities and particle sizes, highlighting the importance of choosing the right protein powder packing machine factory for your production needs.

Using the right container and packaging solution is crucial to maintaining the integrity of protein powders. Whether the product is a fine powder or a mix with small particulates, modern packaging machines – including Vertical Packaging Machines, Doypack Packaging Machines, and multi-head packaging lines – are designed to handle each type efficiently.

The Step-by-Step Protein Powder Manufacturing Process

The manufacturing process for protein powders is both complex and fascinating, requiring precision at every stage. Below is an outline of the typical steps involved, with a special emphasis on the role of the protein powder packing machine in the final stages:

1. Raw Material Selection and Quality Control

The process begins with the careful selection of raw materials, including high-quality protein sources. Quality control measures ensure that the ingredients meet strict nutritional and safety standards.

2. Extraction and Processing

Once the raw materials are chosen, extraction methods are used to isolate the protein. Techniques vary depending on the source, but the goal is always to achieve a high concentration of protein while minimizing impurities.

3. Drying and Powdering

After extraction, the liquid protein undergoes drying (often through spray drying) to create a fine powder. This powder is then milled and sieved to achieve a uniform particle size, a critical step before packaging.

4. Blending and Flavoring

In this stage, additional ingredients such as flavors, sweeteners, and nutritional additives are mixed with the protein powder. The blending process must be precise, as even distribution of additives ensures consistent taste and nutritional value.

5. Packaging

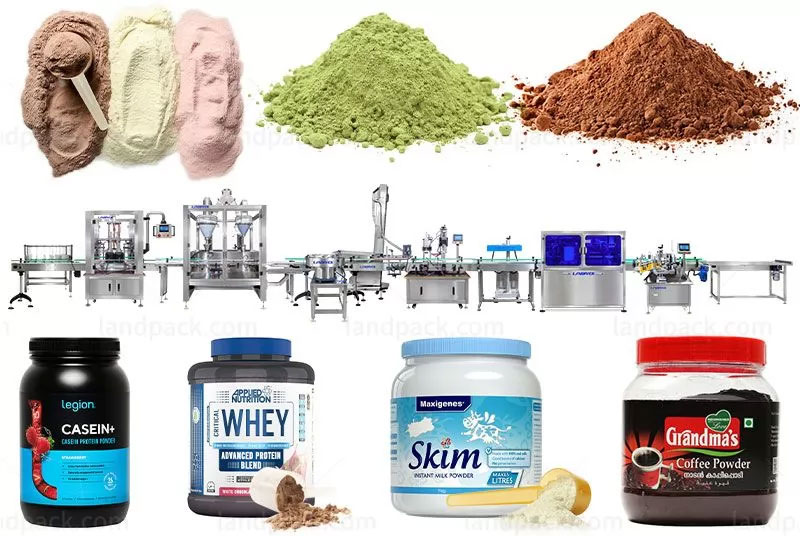

Finally, the protein powder is packaged using advanced protein powder packing machine systems. These machines are designed to fill containers—ranging from small sachets to large bulk packaging—with remarkable accuracy. They come in various configurations, such as:

- Vertical Packaging Machine: Ideal for high-speed, efficient packaging.

- Doypack Packaging Machine: Perfect for packaging in flexible pouches.

- Multi Lane Sachet Stick Filling Machine: Capable of filling multiple containers simultaneously.

- Filling Machine: Used for precise liquid and powder filling.

- Multi Lane Packaging Line: Integrate several packaging processes into one streamlined line.

- Filling Line: Automated systems that ensure continuous, high-volume packaging.

The packaging stage is critical for protecting the product from moisture, light, and contamination. It also plays a key role in branding and consumer appeal. High-quality packaging, often achieved by collaborating with a leading protein powder packing machine factory, guarantees that every package meets industry standards.

What to Consider When Buying Protein Powder

When investing in a protein powder packing machine, there are several important factors to consider to ensure you select the best equipment for your manufacturing process:

1. Container Compatibility

Different protein powders may require different types of containers—whether it's a flexible pouch, a jar, or a bottle. Make sure the packaging machine is compatible with the container types you plan to use. The machine should be capable of handling various sizes and materials without compromising on speed or accuracy.

2. Production Speed and Efficiency

High-volume production demands machines that operate quickly without sacrificing precision. Consider the machine's throughput and whether it integrates well with your overall production line.

3. Customization and Flexibility

A versatile protein powder packing machine should offer customizable options to suit your specific product requirements. For instance, if you plan to produce specialized formulas such as chia protein powder, the machine must accommodate the unique characteristics of the ingredient.

4. Quality Control Features

Look for advanced features such as automated weight checks, metal detectors, and sealing monitors to ensure every package meets strict quality standards. Consistency is key in the supplement industry, and modern packaging machines provide the technology to achieve this.

5. Maintenance and Support

Consider the after-sales support and maintenance services provided by the manufacturer. A reliable protein powder packing machine factory will offer comprehensive service packages, training, and readily available spare parts to minimize downtime.

6. Cost and Return on Investment (ROI)

While the initial investment may be high, high-quality packaging machinery can significantly improve production efficiency and reduce waste. Evaluate the long-term ROI by considering energy consumption, production speed, and the overall durability of the machine.

Choosing the Right Protein Powder Packing Machine: A Guide to Machine Types and Their Advantages

Selecting the appropriate machinery for your protein powder packaging needs is critical for optimizing production and ensuring product integrity. Let's take a closer look at the different types of machines available and their respective advantages:

Vertical Packaging Machine

**Advantages**

- High-Speed Operation: Vertical machines are designed for rapid packaging, making them ideal for large-scale production.

- Space Efficiency: They occupy a smaller footprint compared to horizontal models.

- Ease of Operation: User-friendly interfaces and automation reduce the need for extensive operator training.

Vertical machines are commonly used for packaging dry powders, and their precision is enhanced by advanced sensors and control systems.

Doypack Packaging Machine

**Advantages**

- Versatility: Perfect for flexible packaging, these machines handle various pouch sizes and materials.

- Product Protection: Pouches are excellent at protecting sensitive protein powders from environmental factors.

- Cost-Effective: Lower packaging material costs and reduced waste make them an attractive option for manufacturers.

Multi Lane Sachet Stick Filling Machine Line

**Advantages**

- High Throughput: Multiple filling heads ensure that large volumes of protein powder are processed simultaneously.

- Accuracy: Advanced weighing systems guarantee that each pouch or container receives the exact amount of product.

- Scalability: These machines are ideal for companies looking to expand their production capacity.

- Comprehensive Packaging: These lines combine filling, sealing, and labeling into a single integrated process.

For example, the chia protein powder packing machine variant of these systems is specially engineered to handle the delicate nature of chia-based protein powders, ensuring even distribution and accurate dosing.

Filling Machine and Filling Line

**Advantages**

- Continuous Operation: Automated filling lines are designed for non-stop operation, which is crucial for meeting high demand.

- Consistency: Automated filling minimizes human error, ensuring uniformity in every package.

- Integration: These machines can be integrated into a fully automated production line, enhancing overall efficiency.

Each machine type offers unique benefits, and selecting the right one depends on your product's characteristics and production needs. Working with a reputable protein powder packing machine factory, such as Landpack Packaging Machinery Co., Ltd., ensures you get customized solutions designed to meet your specific requirements.

Introducing Landpack Packaging Machinery Co., Ltd.

When it comes to precision and reliability, Landpack Packaging Machinery Co., Ltd. (Landpack) stands out as a leader in the industry. With years of experience, a state-of-the-art factory, and a team of experts dedicated to innovation, Landpack offers a comprehensive range of packaging machinery designed specifically for the protein powder industry.

Why Choose Landpack?

- Factory-Direct Advantage: Landpack manufactures its machines in-house, ensuring strict quality control and competitive pricing.

- Customization: Understanding that every manufacturer's needs are unique, Landpack provides customizable solutions. Whether you require a vertical machine, a pouch filling machine, or a multi-head packaging line, Landpack's engineers will work with you to design a system that perfectly suits your production line.

- Certification and Quality Assurance: With a full suite of certifications, Landpack's machines meet international standards, ensuring reliability and safety.

- Expert Support: From installation to after-sales service, Landpack offers comprehensive support, ensuring that your protein powder packing machine performs at its best.

By partnering with a reputable provider like Landpack, you can be confident that your packaging processes will be efficient, precise, and tailored to the ever-growing demands of the protein powder market.

Advantages of Using Advanced Protein Powder Packing Machines

Adopting advanced packaging solutions offers numerous advantages beyond mere speed. Here are some key benefits:

Enhanced Product Quality

Modern protein powder packing machine systems are engineered to protect the product from moisture, contaminants, and degradation. This ensures that the final product retains its nutritional value and meets regulatory standards.

Increased Efficiency and Throughput

Automated filling and packaging systems reduce manual labor, minimize errors, and significantly increase production speeds. This efficiency translates to lower operating costs and a faster turnaround time from production to market.

Versatile Packaging Options

With a variety of machine types available—including vertical machines, pouch filling machines, multi-head machines, and complete filling lines—manufacturers can choose the perfect solution for their specific container and product requirements.

Improved Consistency and Accuracy

Precision weighing and filling technologies ensure that each package contains the exact amount of protein powder, maintaining consistency across batches and enhancing consumer trust in your brand.

Scalability and Flexibility

As your production demands grow, advanced packaging systems can be easily upgraded or integrated with additional modules. This scalability makes it possible to expand your operations without investing in entirely new infrastructure.

Conclusion: Embrace the Future with the Right Protein Powder Packing Machine

In summary, the role of a protein powder packing machine in the manufacturing process cannot be overstated. From ensuring product integrity to streamlining production, the right packaging machinery is a cornerstone of success in the competitive protein supplement market. By understanding the various types of protein powders, their manufacturing processes, and the technology behind modern packing machines—including options like chia protein powder packing machines and multi-head packaging lines—you are better equipped to make informed decisions.

Partnering with a trusted provider like Landpack Packaging Machinery Co., Ltd. ensures that your investment not only meets today's standards but is also ready for future challenges. With innovative solutions, customizable options, and a commitment to quality, Landpack is your ideal partner in revolutionizing the packaging process for protein powders.

Embrace the future of protein powder manufacturing with advanced, reliable, and efficient packing solutions. The next step towards boosting production efficiency and ensuring consumer satisfaction begins with the right protein powder packing machine. Invest wisely and watch your business flourish in this thriving industry!