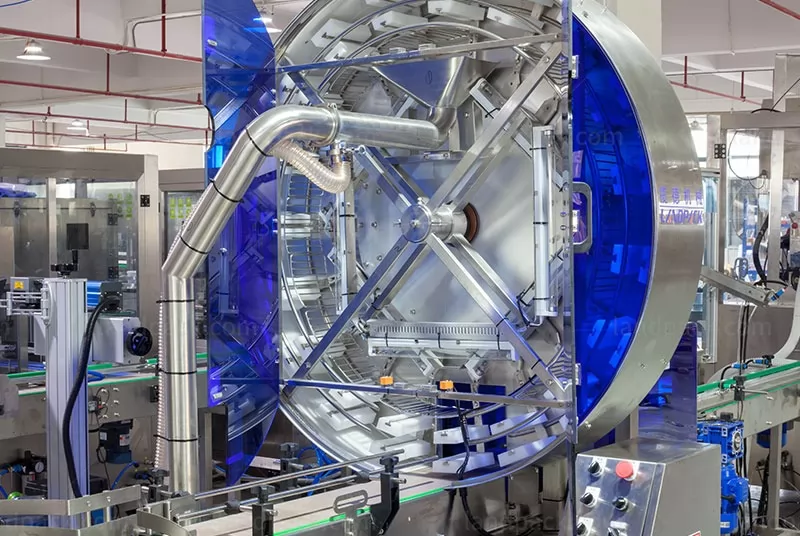

UV Cleaning Blowing Machine |

Item | Specifications |

Voltage | 220V/50Hz (customized) |

Power | 2500W |

Air pressure | 0.3-0.5mpa |

Speed | 10-50 BPM |

Bottle diameter | 76-140mm |

Bottle high | 80-200mm |

UV light | 7 |

Outline dimension | 2400*1300*2200MM |

Net weight | 350KG |

Spoons vibration feeder |

Voltage | 220V/50Hz (customized) |

Power | 300W |

Speed | 10-40 BPM |

Vibration top diameter | 60-80cm |

Spoon size | customized |

Outline dimension | 1000*800*1200MM |

Net weight | 150KG |

Auger Filler (powder dosing) |

Max Weight | 10~1000g/time |

Container size | Φ 80-210mm H100-330mm(customized) |

Filling weight | 900g-2500g(customized) |

Filling accuracy | 500g,≤±1% |

Filling speed | 10~30bottles/min(depend on the material and weight) |

Auger Filler hopper | 50L |

Power supply | Three phase380V or single phase |

Total power | 3.5 KW |

Total weight | 420kg |

Dimension | 2000*900*1850mm |

Automatic Can Seamer Machine |

Bottle type | round, square bottles, etc need to be customized. |

Can body max diameter | 153mm(can be customized) |

Bottle height | 50-150mm(can be customized) |

Speed | 5-8BPM(it depends on product) |

Seaming Type | Nitrogen consumption and vacuum seaming |

Caps feeding type | Automatic lids feeding |

Machine voltage | 220V(can be customized) |

Machine size | 2000*1000*1700mm |

Machine weight | 550kg |

Laser Printer |

power | 20~200W (can be option) |

Laser | 1064mm |

repeat frequency | 20~200KHZ |

basement membrane Gaussian beam | <1.2 |

Printing range | 100*100mm |

Engraving | <0.4mm |

Speed | Max 10000mm/s |

Minimum Line Width | 0.01mm |

Minimum character | 0.15mm |

Accuracy | ±0.02 |

Power supply | 220V/50Hz, 500W |

Positioning way | Infrared focusing |

Machine size | 825*545*1425mm |

Machine Weight | 60kg |

Operating system | Embedded touch marking system or external 10.1 inch |

Cooling method | Built-in air cooling |

Control interface | Standard USB |

File format | All fonts/glyphs of WINDOWS operating system fonts |

Laser type | Air-cooled fiber laser; Service life of up to 100,000 hours |

Automatic Cans cleaning machine |

Speed | 20-40bpm |

Bottle diameter | 80-210mm (or custom-made) |

Power | 2KW 380V |

Weight | 350KG |

Machine size | 1700*800*1800mm |

Automatic lids pressing machine |

Material | 304 stainless steel |

Cover size | Cover diameter: 40-130mm (can be custom-made) |

cover height | 5-15mm |

Bottle diameter | 50-220mm |

Speed | 10-50 bottles/minute |

Conveyor belt size | (L)1900mm*(H)900*(W)114mm |

Machine size | (L)1900mm*(H)1700*(W)800mm |

Weight | 250KG |

Power | 220V, 50HZ, 0.68KW |

Air pressure | 0.5-0.7MPa, require 750W air compressor |