- Home

- About Us

-

Products

- Hot Products

- Filling Machine/ Line

- Complete Packing Line

-

Doypack Machine

- Doypack Packaging Machine

- Rotary Premade Pouch Packing Machine

- Horizontal Premade Pouch Packing Machine

- Mini Doypack Packing Machine

- Automatic Vacuum Packing Machine

- Spout Pouch Filling Machine

- Zipper Pouch Packing Machine

- Stand Up Pouch Packing Machine

- Retort Pouch Packaging Machine

- M Shape Pouch Packing Machine

- Sachet/ Stick Pack Machine

- Vertical Form Fill Seal Machine(VFFS)

-

Granular Packing Machine

- Granule Packing Machine

- Multihead Weigher Packing Machine

- Chips Packing Machine

- Snacks Packing Machine

- Dried Fruits Packing Pachine

- Sugar/ Salt Packing Machine

- Grain Packing Machine

- Candy Packing Machine

- Seeds Packing Machine

- Popcorn Packing Machine

- Nuts/ Cashew/ Beans Packing Machine

- Frozen Food Packaging Machine

- Dry Food Packing Machine

- Fastener Packing Machine

- Pet Food Packing Machine

- Cannabis Packaging Machine

- Jerky Packaging Machine

- Silica Gel Packing Machine

- Fertilizer Packing Machine

- Mesh Bag Packing Machine

-

Liquid Packing Machine

- Liquid Packaging Machine

- Oil Packing Machine

- Juice Packing Machine

- Sauce/ Jam Filling Machine

- Shampoo Filling Machine

- Honey Packing Machine

- Hand Sanitizer Filling Machine

- Ketchup Packing Machine

- Paste Packing Machine

- Popsicle Packing Machine

- Mayonnaise Packing Machine

- Pickles Packing Machine

- Ghee Packing Machine

- Alcohol Liquor Filling Machine

- Peanut Butter Filling Machine

- Chemical Filling Machine

- Garlic Filling Machine

- Liquid Soap Filling Machine

- Chutney Packing Machine

- Vinegar Filling Machine

- Powder Packing Machine

-

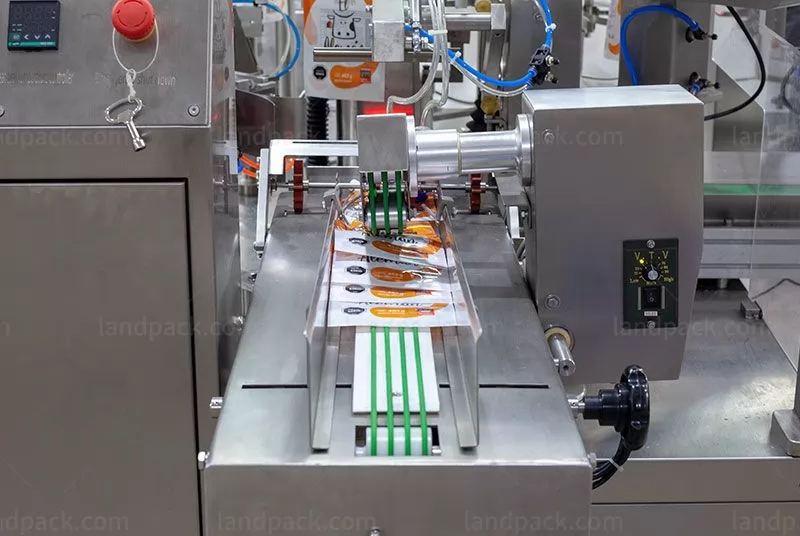

Flow Pack Machine

- Flow Wrap Machine

- Automatic Feeding Packing Line

- Vegetable/ Fruit Packing Machine

- Cutlery Packing Machine

- Noodles Packing Machine

- Masк Packing Machine

- Swab Packaging Machine

- Cartoning Machine

- Sanitary Pads Packaging Machine

- Biscuit Packing Machine Line

- Bread Packing Machine Line

- Bun Packing Machine Line

- Rusk Packing Machine Line

- Soap Packing Machine Line

- Wafer Packing Machine Line

- Chocolate Packing Machine Line

- Tube Filling And Sealing Machine

- Pharma Packaging Machine

- Coffee Packaging Machine

- Supporting Equipment

- Solution

- Support

- News

- Contact Us