1. Versatile Pouch Compatibility: Suitable for various pre-made retort pouch types, including flat and stand-up pouches, with or without zippers, accommodating diverse packaging needs.

2. User-Friendly Operation: Equipped with a PLC control system and color touchscreen for easy adjustments, with fault indications directly on the panel for quick troubleshooting.

3. Quick Adjustment: Pouch changeover takes only about 10 minutes, increasing production efficiency.

4. Variable Speed Control: Speed is adjustable through frequency conversion, providing flexible production rates.

5. Waterproof Design: The machine surface is washable for easy cleaning and enhanced durability, promoting a longer service life.

6. Automated Error Detection: The machine alarms and halts if there is no pouch or an improperly opened pouch, preventing waste by stopping the fill and seal processes.

7. Air Pressure Monitoring: Automatically alarms and stops if air pressure is inadequate, ensuring stable operation.

8. Safety Features: Equipped with safety guards and safety switches, the machine stops and alarms if guards are opened.

9. Hygienic Stainless Steel Construction: All product-contacting parts use SUS304 stainless steel for sanitary handling.

10. Non-Contaminating Bearings: Imported engineering plastic bearings eliminate the need for oiling, ensuring clean operation.

11. Oil-Free Vacuum Pump: The oil-free pump design avoids environmental contamination, maintaining a clean production space.

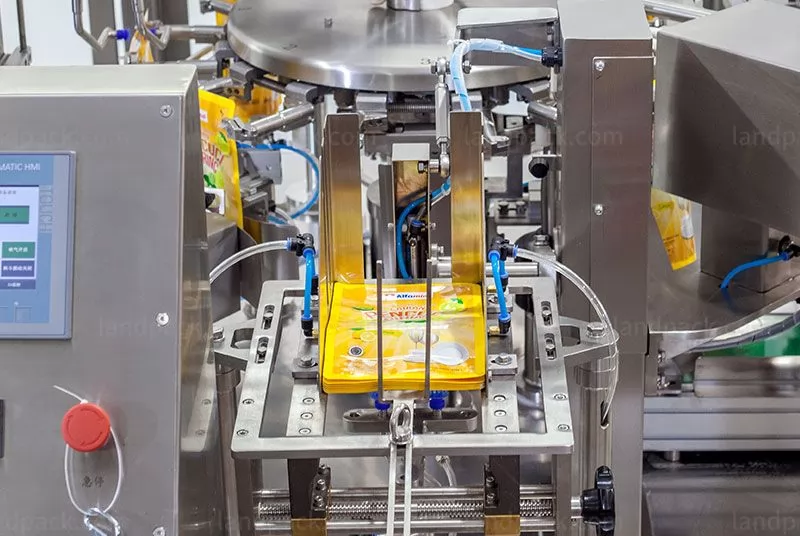

Workflow:

1. Giving bag

2. Coding

3. Opening

4. Filling 1

5. Filling 2

6. Auxiliary exhaust

7. Heat sealing

8. Forming and output product