Standard Equipment Parts:

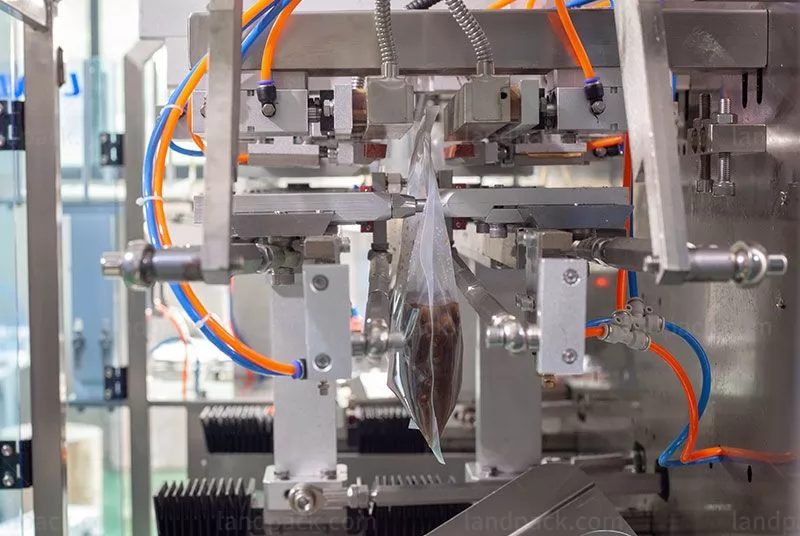

1.The couch screen; 2. PLC control system; 3. Cylinder; 4.Temperature controller; 5. bag depositor; 6. Bag gripper; 7. Bag hopper; 8.Pouch opening devices

Auxiliary function device (optional):

1.zipper opener; 2.protect the clip; 3. vacuum pump

Standard Features:

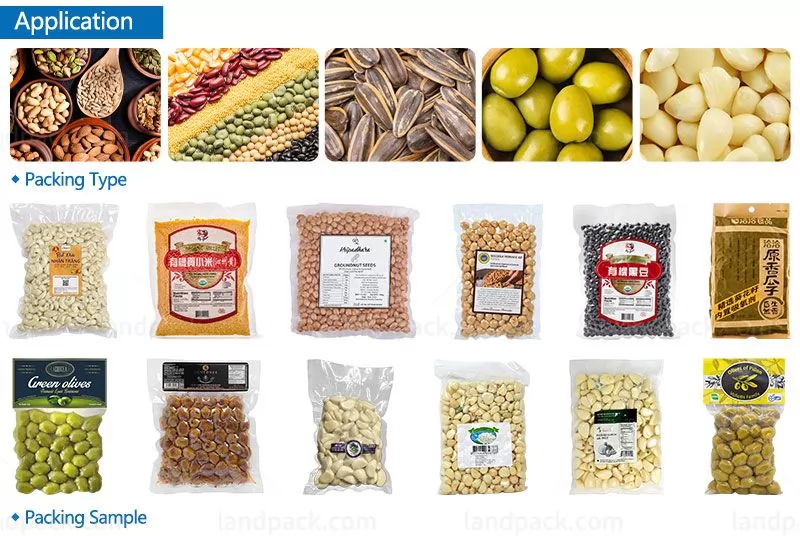

1. Machine is specially developed for all kinds of composite composite pre-made bags.

2. PLC & HMI Control , Easy for parameter setting and troubleshooting.

3. Different pouch size adaption, simple adjustment without tools.

4. Intelligent temperature controlling configuration, ensure the artisticand neat sealing.

5. Pouch saving design,no completely opened pouch,no filling and sealing.

6. Compatible Programs of powder, granule or liquid dosing, easy for different products switching.

7. Machine stoped when the door is opened.

Optional Features

1. Pouch zipper opening function.

2. Gusset pouch opening function.

3. Gas flush function to keep the products fresh and avoid them broken.

4. Air/Nitrogen Inflating, Air deflating function.

5. Vacuum function to keep the products fresh and reduce the package space.

6. Bag tapper vibrating compacting function help products drop to the bag bottom part and enhance packaging density.

7. Grip seal to avoid powders coming out during filling.

8. Dedusting device to enable clean packaging environment and ensure quality of sealing.

9. Different types of codeprinting function, such as hot stamp ribbon printer, inkjet printer, thermal transfer printer and so on.