1. Sturdy 304 Stainless Steel Construction: 304 stainless steel frame, meeting food QS and pharmaceutical GMP cleanliness.

2. State-of-the-art Safety mechanisms: With smart safety features satisfying industry safety standards, this device enhances the security of operations.

3. Top-quality Electrical Parts: High-grade electrical configurations by world-renowned companies.

4. Smart PLC & Touch Screen Control: Using Siemens PLC, can realize full automatic, high speed and reliable operation.

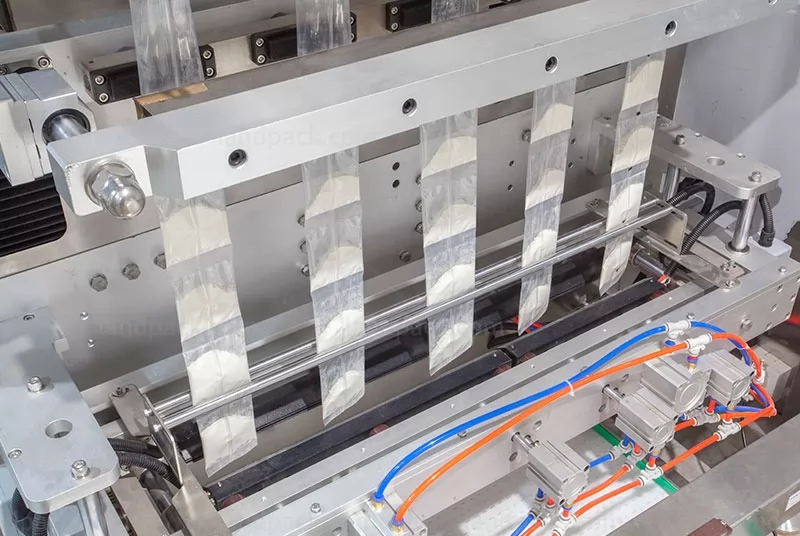

5. Precision film managing system: Servo motor driven film transport, color mark detection for accurate bag positioning and monitor adjustments by touch screen.

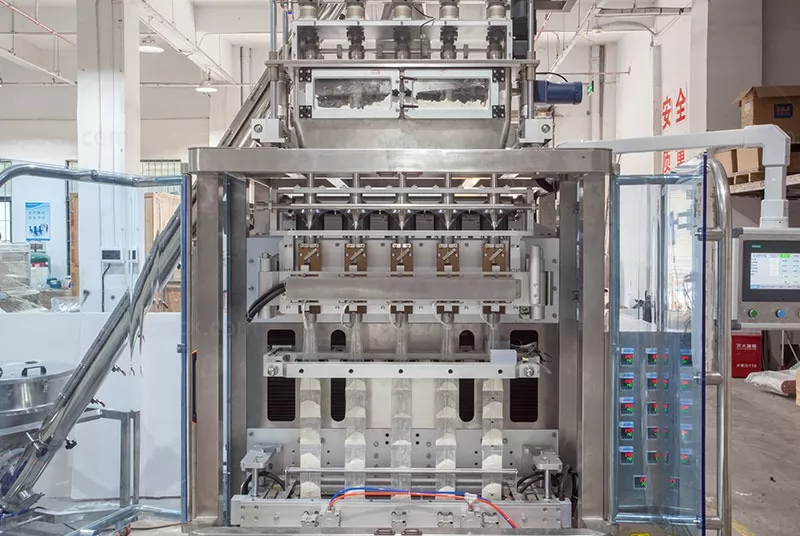

6. Support of multi-row packaging Capability: Configured supporting up to 4 - 12 concurrent rows as per bag size to optimize efficiency.

7. Easy Integration Into Downstream Systems: The machine seamlessly connects to ingredient feeding systems and automatic cartoning units for a fully automated packaging line.

8. Performance Is Fast And Consistent: It is designed to work at high speed and very low downtime, providing fast and consistent production.

9. A Package Adaptable to Multipurpose Styles: Suitable for different bag styles and materials appropriate to the product.

10. Low Maintenance & Easy to Clean: Features hygiene and easy cleaning components, limiting maintenance time and saving future maintenance costs.

Workflow:

1. Packing flim running system

2. Laser printer

3. Auger screws measuring system

4. Auger screws filling system to fill the powder

5. Heat sealing and continuous packaging for output