1. It integrates storage, sort mixing, feeding, filling, packing, sealing and output. Production Process: Includes weight checking and automatic rejection for safe, labor-saving production process.

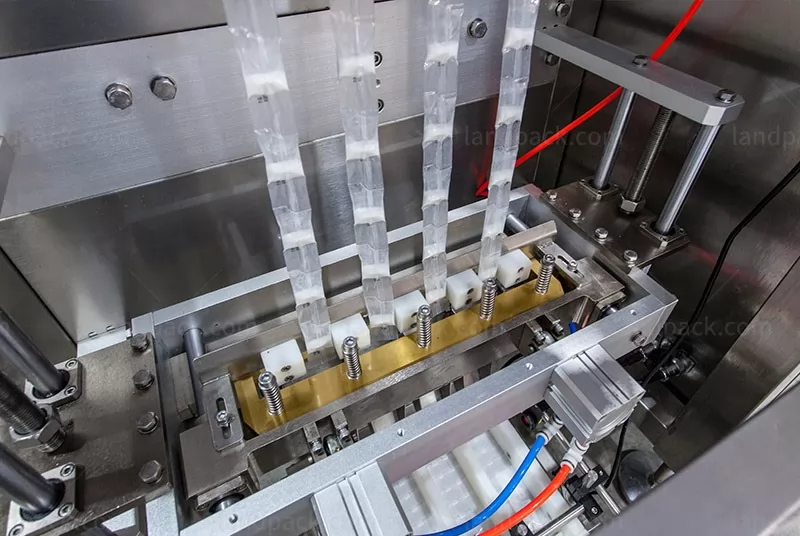

2. Auger screws ensure stable and accurate powder filling specific to a type of powder and then sealed clean and firm with high-quality packaging.

3. Measuring vision on automatic machine square to weight inspection immediately responsible for weight test on product ensures the quality of product.

4. Fully automated production makes it a high-speed, zero-human intervention, and consistent output process.

5. The factory operates under stringent safety protocols that ensure a hygienic production line with minimum manual intervention in the process.

6. With high precision in powder dosing, filling, and sealing, the system's sophisticated technology ensures uniformity in product quality and packaging performance.

Workflow:

1. Storage tank for powder materials

2. Auto vacuum feeding the powder to the mixer tank

3. Storage tank for the ready powder

4. Auto vacuum feeding the powder to the packing machine

5. Packing flim running system

6. Date & Production code printer

7. Auger screws measuring system

8. Auto making the stick bag

9. Auger screws filling system to filling the powder

10. Heat sealing and cutting - Output

11. Weight checking and reject